Generally large-scale jam processing plants use vacuum concentrators to produce jams, but vacuum concentrators are expensive to manufacture and not acceptable to every investor. Small factories can use simple equipment to produce jams.

The jam is made of fruits, processed by de-nucleating and peeling, boiled and beaten, added sugar and concentrated, added stabilizers, preservatives, etc., adjust the acidity, that is the finished product. The taste of jam is moderately sweet and sour, and nutritious. It is a convenient food for western food, picnics, tourism, and field operations. It is also one of the necessary raw materials for pastry fillings and cold drink sandwiches. It is very popular in the market.

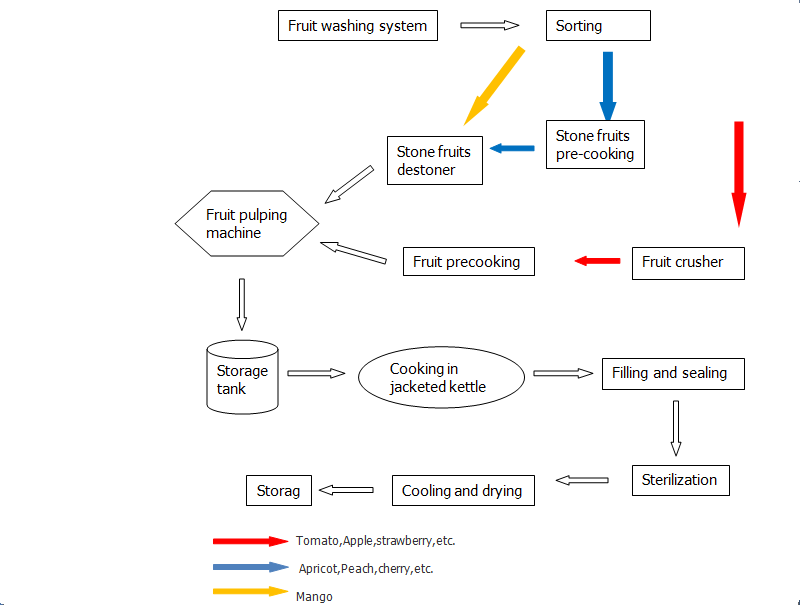

The processing of fruit jam is not complicated. Generally, you should master the following technical:

1. Processing fresh fruit. There are many fruits for making jams, such as apple, hawthorn, strawberry, kiwi, citrus, etc. Fruits with high maturity are required and have higher pectin and fruit acid content. Remove the rotten and inferior fruits from the selected fruits, remove the seeds, peel, and slice, and put them in a citric acid aqueous solution or saline solution to soak and protect the color.

2. Soften fruit and pulping. To process the fruit into jam, it must be pre-cooked to soften it. Pre-Cooking the fruit using a jacketed kettle. Add fruit and an equal amount of water to the jacketed kettle, cooking until soft. Use a pulping machine to process pre-cooked softened fruit into a pulp. The standard of the fruit pulp should be soft, even, no-granular, free of impurities and pure in color.

3. Making jam. The sugar content of the fruit pulp should be above 65%, and the acidity is equivalent to 0.7% containing citric acid. When making jam, the fruit pulp must be concentrated, that needs the use of a jacketed kettle with mixer and continuous stirring to prevent caking and scorched. After condensing the jam to more than 65% sugar content, add stabilizers and preservatives, mix evenly, add acid to adjust the flavor, and stirring evenly.

4. Filling and Sterilizing. The processed jam should be filled while hot, and the temperature after filling should not less than 85℃. After sealing, put the bottle into boiling water (Sterilization machine) or steam for about 20 minutes to sterilize, then cool it in stages and dry the bottle.

Flow chart:

Name: Gavin

Mobile: +86 181 3273 1506

Email: oath1@bdoath.com

WhatsApp: +86 181 3273 1506

Add.: No. 79, Swan Road, Gaokai District, Baoding, Hebei, China.